Continental leads consortium of eight partners from industry and research

Continental is digitalizing the entire production process for automotive components. To this end, the technology company has formed a partner consortium with a total of eight renowned IT and process optimization companies, universities and specialist start-ups. Continental’s User Experience business area is responsible for project management. The three-year project is called “Digitalization of the Industrialization Process in the Automotive and Supplier Industries” (or DIAZI) and is funded by the German Federal Ministry for Economic Affairs and Climate Action.

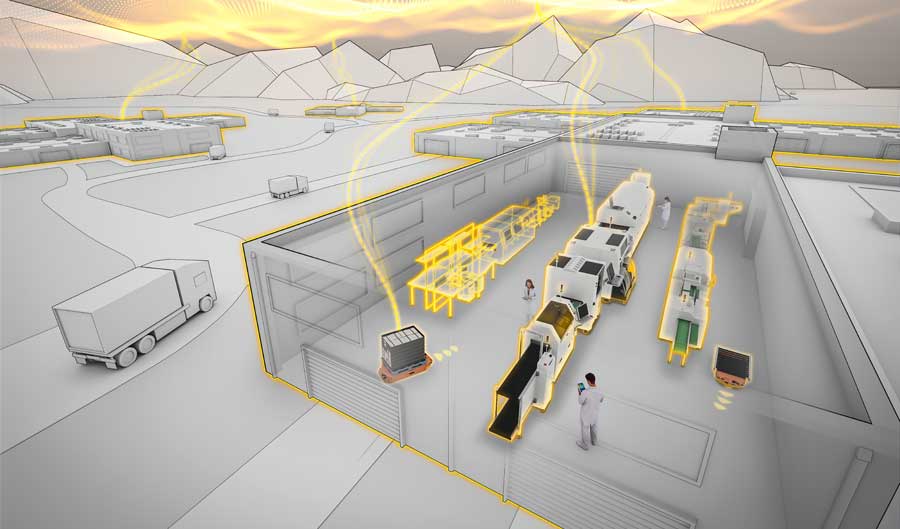

The aim of the DIAZI project is to transfer production plants into the digital world. In the future, new production lines will be planned, simulated and operated digitally, increasing the efficiency, flexibility and cost-effectiveness of modern automotive plants and allowing them to keep pace with faster development cycles, complex supply chains and changing customer requirements. The results of the DIAZI project will make the industrialization of the automotive industry much more effective – and thus contribute to sustainable mobility as a whole.

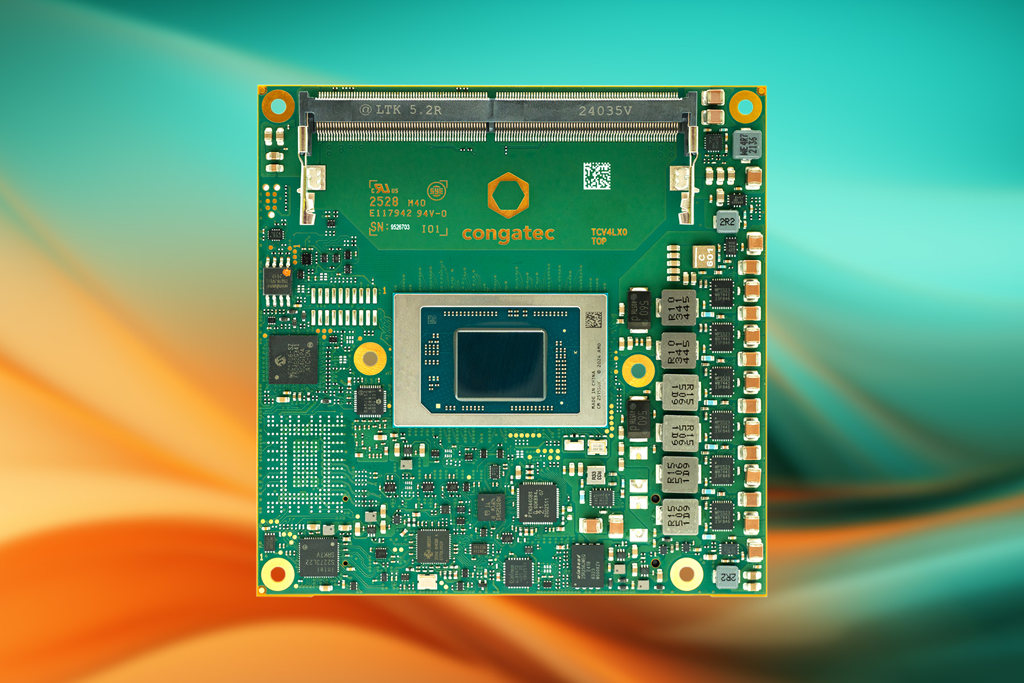

“DIAZI is a major step toward the digitalization of the automotive industry,” explains Thomas Ebenhöch, head of operations for the User Experience (UX) business area in Continental Automotive. “As the lead company in the DIAZI project, Continental is driving a new approach to effective and sustainable production processes in the automotive and supplier industries. We’re already a leader in the development of digital components such as intelligent display solutions. Now, through digital simulation, artificial intelligence and data management in the cloud, we’re bringing innovations to market faster, more efficiently, more sustainably and more cost-effectively across the manufacturing industry. Early results show we’re on the right track. Our vision of the ‘digital factory’ is clearly taking shape.”

“Digital factory”: innovative updates to the entire production process

The infrastructure of the German automotive and supplier industries will benefit greatly from a digital update. In view of the increasing competition in key technologies, a holistic, digitally driven approach to optimizing industrialization processes is increasingly important. This is the only way to adapt to increasing customer requirements and faster development cycles.

The DIAZI project promotes the “digital factory”: a fully digitalized production environment in which new production lines are digitally planned and production processes are simulated. In this way, new production plants can first be started up virtually before commissioning. Driven by artificial intelligence, this step makes it possible to continuously optimize processes, make accurate productivity predictions and minimize downtime thanks to in-depth data analysis of all machines. Various production plants of a company, as well as production sites of suppliers, can thus be connected to ensure fast, scalable and high-quality production.

Groundbreaking findings for the entire automotive industry

The project, which is funded by the German Federal Ministry for Economic Affairs and Climate Action and financed by the European Reconstruction and Resilience Facility, started on January 1, 2023, and is designed to run for around three years. “The dynamic transformation of the automotive sector into a highly digitalized industry offers enormous potential”, says Ernst Stöckl-Pukall, head of Digitalization, Industry 4.0 at the Federal Ministry for Economic Affairs and Climate Action. “Cooperation across company boundaries, as practiced in the DIAZI project, represent a key component for the entire industry. The findings and demonstrators from the project have the potential to be adapted to numerous companies and production lines and serve as an impulse generator for fully digitalized and AI-supported production processes.”

The first phase of the project, which has now been completed, aimed to define specific demonstration models within various fields of digitalization in order to include the entire virtual line planning and commissioning process, from data-based process optimization to application operation. Experts from Landshut University of Applied Sciences, the Technical University of Braunschweig, the software start-up IFOX Systems, the IT management company Suse, the intralogistics expert Naise, the process and production optimizer Dualis and plus10, a provider of analysis software for automated production plants, were involved in the process.

Continental customers are already benefiting from the project’s initial successes

The first successes of the DIAZI project show great potential. For example, the consortium partners in the “Data-based Process Optimization” work package were able to display the complete data stream from several production lines in a newly created cloud environment and prepare it for effective data analysis. This data helped the DIAZI team in the “Virtual Line Planning and Commissioning” work package to simulate production lines and optimize existing production processes. Continental’s customers are already benefiting from this, for example in the accelerated production of new display solutions.

![[심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다 [심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다](https://icnweb.kr/wp-content/uploads/2026/01/memory-market-3player-1024web.png)

![[심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다 [심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다](https://icnweb.kr/wp-content/uploads/2026/01/Perplexity-image-Edge-AI-industry1b-700web.png)

![[심층기획] AI가 다시 쓴 글로벌 혁신의 방정식… “속도전 끝났다, ‘신뢰’와 ‘질’로 승부하라” [심층기획] AI가 다시 쓴 글로벌 혁신의 방정식… “속도전 끝났다, ‘신뢰’와 ‘질’로 승부하라”](https://icnweb.kr/wp-content/uploads/2026/01/Gemini_Generated_Image_100-innovation-1024web.png)

![[피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시” [피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시”](https://icnweb.kr/wp-content/uploads/2026/02/R41_0775-HM26-von-press-900web.png)

![[이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝 [이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝](https://icnweb.kr/wp-content/uploads/2025/07/OT-security-at-automotive-by-Gemini-Veo-1024x582.png)

![[기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지 [기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지](https://icnweb.kr/wp-content/uploads/2026/01/generated-edge-AI-4-in-1-01-1024web.png)

![[그래프] 국회의원 선거 결과 정당별 의석수 (19대-22대) 대한민국 국회의원 선거 결과(정당별 의석 수)](https://icnweb.kr/wp-content/uploads/2025/04/main-image-vote-flo-web-2-324x160.jpg)