In addition to flow, pressure is without doubt the most relevant parameter and measuring factor in hydraulic applications. Measuring system pressure is therefore one of the most important and most frequently used methods for monitoring and controlling machinery and equipment. It is the prerequisite for reliable and economical operation. Analogue or digital gauges are generally used for this. While these are very inexpensive to buy, install and operate, they usually provide no option for recording data for subsequent evaluation and documentation. Users have to resort to more expensive and often also complicated pressure measuring systems with individually wired sensors where the time-consuming installation can sometimes already affect the economic efficiency of a measurement.

The PT-RF series of pressure transmitters presented by Stauff at this year’s Hannover Messe are an in-house development that has a patent pending. This new product in the field of universal pressure measurements for fluid technology applications will provide benefits for system operators, maintenance personnel and repair technicians as well as for original equipment manufacturers.

The use of these transmitters in a hydraulic system allows for the wireless collection of pressure data without having to connect any measuring devices to the user’s equipment, thus eliminating the possibility of introducing contamination into the system and significantly speeding up the process.

The operating principle of the pressure transmitters is based on the RFID (radio frequency identification) technology which has already become established in other areas of work and everyday life. The energy required for a measurement is transferred to the pressure transmitter via the antenna of the associated reading and display device so that the transmitter requires no internal or external power supply in the traditional sense (e.g. in the form of a battery) and no external wiring as it is common for conventional sensors. All that is required is a maximum distance of 1.5 centimetres from the antenna to the tip of the pressure transmitter for the duration of the measurement.

When the pressure transmitter is activated by the press of a button, the current pressure is determined in less than 0.5 seconds and then immediately transmitted back to the hand-held reader, displayed and stored for further evaluation. In addition to the pressure value itself, other relevant information is also transmitted as a standard, including media temperature, date and time of the measurement and the unique serial number of the pressure transmitter. When a continuous measurement is triggered, the MIN and MAX values as well as the average values for the respective time period are displayed in addition to the most recent pressure and temperature values. Over 15,000 of these measurement sets can be stored in the integrated memory of the reading device. The software included with the unit allows subsequent evaluation and further processing of the measurement results previously transmitted to the PC or notebook via the USB interface.

The pressure transmitters are available in five different versions and cover the usual measuring ranges for hydraulics between 0 … 16 bar and 0 … 600 bar (relative), depending on requirements, with a precision of max ±0.5 per cent full scale. The results can also be displayed in PSI. Temperature values can be displayed from -40 °C … +85 °C (or from -40 °F … +185 °F respectively).

Due to the stainless steel housing and the fully enclosed internal parts, pressure transmitters from the PT-RF series are hermetically sealed and can also be used under rough conditions (IP67 protection rating). As all parts that come into contact with media are also made of stainless steel, the system can be used with a variety of aggressive media as well. With a weight of only 220 grams, the reading and display device features a handy and most convenient design that is also robust (IP65 protection rating) and intended for regular use during a long lifetime.

The pressure transmitters are available with 1/4″ BSPP (with FPM profile sealing rings) or 1/4″ NPT screw-in threads thus ensuring easy integration with existing machinery during planning and design of the system, or in existing machinery or systems. Using suitable adapters based on straight 24°cutting ring fittings as per ISO 8434-1 and DIN 2353, the transmitters can also be easily installed in metric pipes with outer diameters between 6 and 42 millimetres which are commonly used in hydraulics. The corresponding connection pieces are available for the temporary or permanent use of existing test couplings with adapter thread M16x2 (e.g. from the Stauff Test 20 series).

The advantages resulting from the use of the new technology for system operators, maintenance personnel and repair technicians are clear: Measurements can be carried very easily, without extensive training and within a few seconds at the press of a button and then documented in a reliable process. Unscrewing and re-installing pressure gauges or other measuring and display devices – practically a temporary opening of the system – is not required. Potential hazards for people, machines and the environment, for example from emitted residual oil in the test hose or leaks at the measuring point, as well as ingress of dirt into the system (e.g. in dusty environments) can be effectively excluded.

If the pressure transmitters are installed directly in the system or pipeline for permanent use, they protrude only slightly more than conventional hydraulic test couplings and meet the highest demands with regard to space requirements and weight.

For original equipment, mechanical engineering companies and line builders will also benefit from this new product: If the pressure transmitters are installed at the factory, the innovative technology can provide a competitive edge over alternative suppliers and open up specific advantages for the users, increasing the value retention of their own devices in the long term.

Interested visitors of the Hannover Messe 2015 will find further information at booth D21 in hall 21, as well as at www.stauff.com.

www.icnweb.co.kr

[HannoverMesse] pressure transmitters for Wireless measuring by Stauff

뉴스레터 구독하기

아이씨엔매거진은 AIoT, IIoT 및 Digital Twin을 통한 제조업 디지털전환 애널리틱스를 제공합니다.

테크리포트: 스마트제조, 전력전자, 모빌리티, 로보틱스, 스마트농업

[피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의...

2026 하노버산업박람회는 인공지능(AI)이 주도하는 제조 혁신과 새롭게 추가된 방위산업 생산 기술을 통해 우리 삶을 바꾸는 미래 산업의 청사진을 제시한다

ABB, ‘Automation Extended’ 공개… DCS 현대화 및 가용성 확보의 새 이정표...

글로벌 기업 ABB가 공장을 멈추지 않고도 인공지능 같은 최신 기술을 손쉽게 추가할 수 있는 새로운 시스템 관리 프로그램을 출시하여 공장의 안전과 혁신이라는 두 마리 토끼를 잡았다

슈나이더 일렉트릭, AW 2026서 자율제조 청사진 공개한다

슈나이더 일렉트릭이 AW 2026 전시회에서 인공지능과 소프트웨어를 활용해 공장을 스스로 움직이게 하고 에너지를 절약하는 차세대 자율제조 솔루션을 대거 공개한다

충전기 하나로 모든 기기를… USB-C 설계 혁명 이끄는 STUSB4531 등장

ST마이크로일렉트로닉스가 복잡한 프로그램 설치 없이도 다양한 전자기기를 USB-C 단자로 빠르고 안전하게 충전할 수 있게 해주는 새로운 반도체 칩을 출시했다

“실내외 사각지대 없다” 수년 가는 배터리 갖춘 차세대 IoT 트래커 ‘주노’...

센티넘이 노르딕의 초전력 칩을 사용해 실내외 어디서든 물건의 위치와 상태를 수년간 추적할 수 있는 작고 똑똑한 자산 관리용 트래커를 출시했다

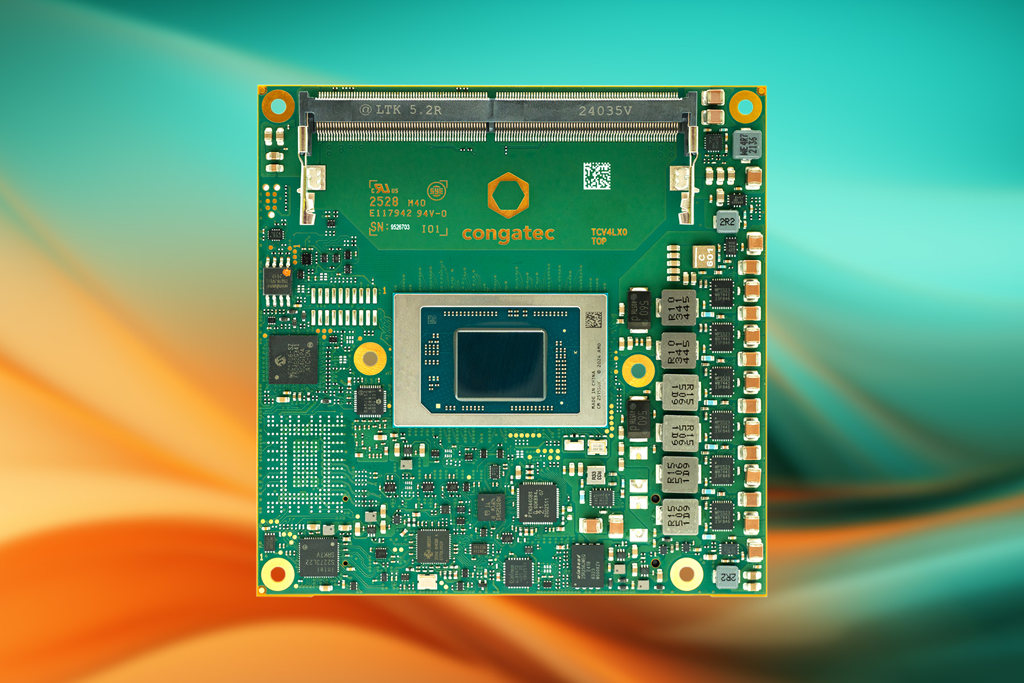

콩가텍, AMD 라이젠 AI 기반 ‘conga-TCRP1’ 모듈 출시… 엣지 AI 한계...

강력한 NPU 성능과 SWaP-C 최적화 설계를 결합한 콩가텍의 신규 모듈은 팬리스 구성이 필요한 가혹한 산업 현장에서 실시간 결정론적 성능을 보장하며 엣지 컴퓨팅의 새로운 표준을 제시한다

노르딕, NPU 탑재 nRF54L 시리즈로 초저전력 엣지 AI 시대 연다

노르딕 세미컨덕터가 초소형 IoT 기기에 AI 인텔리전스를 구현할 수 있는 업계 최고 수준의 초저전력 엣지 AI 솔루션을 공개했다. NPU를 통합한 새로운 초저전력, 대용량 메모리 기반 무선 SoC 이다

![[심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다 [심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다](https://icnweb.kr/wp-content/uploads/2026/01/memory-market-3player-1024web.png)

![[심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다 [심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다](https://icnweb.kr/wp-content/uploads/2026/01/Perplexity-image-Edge-AI-industry1b-700web.png)

![[심층기획] AI가 다시 쓴 글로벌 혁신의 방정식… “속도전 끝났다, ‘신뢰’와 ‘질’로 승부하라” [심층기획] AI가 다시 쓴 글로벌 혁신의 방정식… “속도전 끝났다, ‘신뢰’와 ‘질’로 승부하라”](https://icnweb.kr/wp-content/uploads/2026/01/Gemini_Generated_Image_100-innovation-1024web.png)

![[피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시” [피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시”](https://icnweb.kr/wp-content/uploads/2026/02/R41_0775-HM26-von-press-900web.png)

![[이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝 [이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝](https://icnweb.kr/wp-content/uploads/2025/07/OT-security-at-automotive-by-Gemini-Veo-1024x582.png)

![[기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지 [기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지](https://icnweb.kr/wp-content/uploads/2026/01/generated-edge-AI-4-in-1-01-1024web.png)

![[그래프] 국회의원 선거 결과 정당별 의석수 (19대-22대) 대한민국 국회의원 선거 결과(정당별 의석 수)](https://icnweb.kr/wp-content/uploads/2025/04/main-image-vote-flo-web-2-324x160.jpg)