B&R presenting solutions for tomorrow’s machines in Hanover

According to the Industry 4.0 working group, Smart Factories and the Internet of Things will be reality by 2025. B&R customers will not have to wait nearly that long, however. This innovative specialist in the field of automation offers technologies and solutions that make it possible to implement tomorrow’s machines and systems today. B&R will be presenting their innovative range of products at the Hannover Messe in Hall 9, Booth D28.

“The concepts of the future will thrive on the use of open technologies,” explains Markus Sandhöfner, managing director of B&R Germany. This requirement is already being met by B&R’s Automation Studio software and the open-source POWERLINK and openSAFETY standards. The APROL process control system allows machinery to be quickly and safely interconnected in order to optimize maintenance intervals, overall energy efficiency and the load on individual machines. “This is Industry 4.0 – up close and personal,” says Sandhöfner.

An important step into the future for B&R is the Scalability+ concept, advanced technology that maximizes the overall modularity and flexibility of machines and systems and allows machine manufacturers to select a hardware and software solution that best fits their automation needs – all without having to enter into any kind of commitment. “If the development process determines that components or solutions need to be upgraded or scaled down, this can be done at any time,” says Sandhöfner. Development work that has already been completed is completely retained.

High performance with a compact design

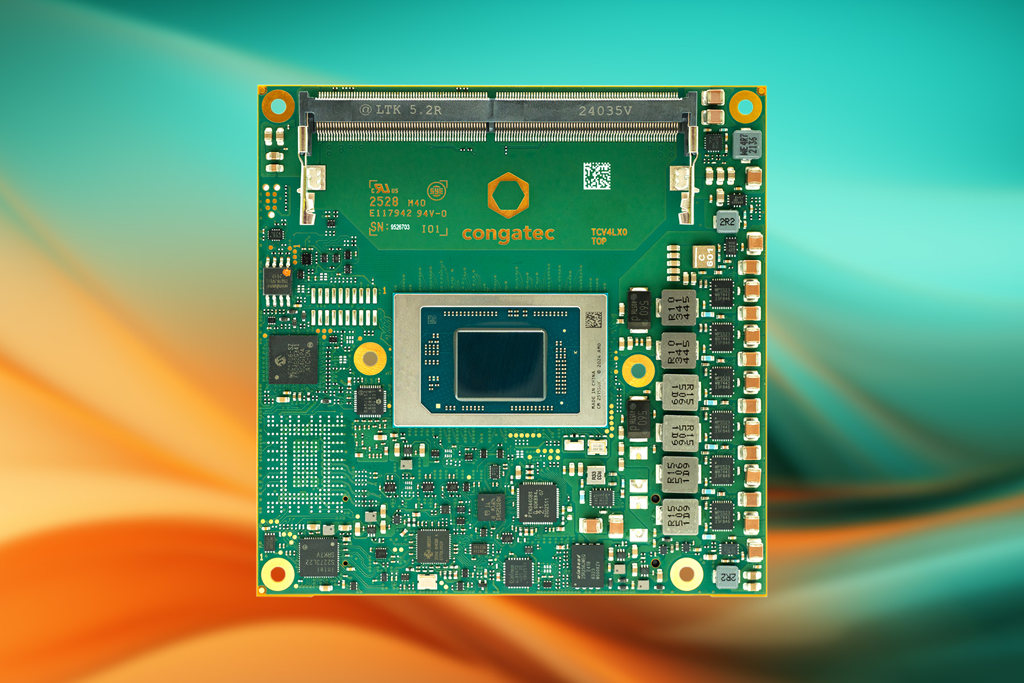

B&Rs modular Panel PC platform is an important component of Scalability+. The newest system in this platform, the Panel PC 2100, will be presented to the public for the first time at the Hannover Messe. All 2nd generation Automation Panels – both the rack-mounted and support arm variants – can be upgraded to a powerful Panel PC system simply by installing the PC module. Taking advantage of innovative Bay Trail architecture from Intel, the PC module is as compact as a DVI/SDL receiver. At the same time, the computing power is fully scalable, with single-core, dual-core or quad-core processors available depending on the actual requirements of the user.

[B&R www.br-automation.com]

![[심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다 [심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다](https://icnweb.kr/wp-content/uploads/2026/01/memory-market-3player-1024web.png)

![[심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다 [심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다](https://icnweb.kr/wp-content/uploads/2026/01/Perplexity-image-Edge-AI-industry1b-700web.png)

![[심층기획] AI가 다시 쓴 글로벌 혁신의 방정식… “속도전 끝났다, ‘신뢰’와 ‘질’로 승부하라” [심층기획] AI가 다시 쓴 글로벌 혁신의 방정식… “속도전 끝났다, ‘신뢰’와 ‘질’로 승부하라”](https://icnweb.kr/wp-content/uploads/2026/01/Gemini_Generated_Image_100-innovation-1024web.png)

![[피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시” [피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시”](https://icnweb.kr/wp-content/uploads/2026/02/R41_0775-HM26-von-press-900web.png)

![[이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝 [이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝](https://icnweb.kr/wp-content/uploads/2025/07/OT-security-at-automotive-by-Gemini-Veo-1024x582.png)

![[기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지 [기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지](https://icnweb.kr/wp-content/uploads/2026/01/generated-edge-AI-4-in-1-01-1024web.png)

![[그래프] 국회의원 선거 결과 정당별 의석수 (19대-22대) 대한민국 국회의원 선거 결과(정당별 의석 수)](https://icnweb.kr/wp-content/uploads/2025/04/main-image-vote-flo-web-2-324x160.jpg)