The ExOne Company, a specialist in industrial sand and metal 3D printers using binder jetting technology, is collaborating with Maxxwell Motors on development of a unique copper e-winding design for its innovative axial flux electric motors, which can be used in electric cars as well as a range of other heavy-duty vehicles and industrial devices.

Founded in 2018 based on a vision of improving how electric motors are designed and manufactured, without rare-earth magnets, Maxxwell holds nine U.S and global patents and has launched two products, a 10 kW air-cooled motor generator and a 150 kW liquid-cooled motor.

The company is led by the team of Chairman Gary Wells, the former CEO and current board member of Wells’ Dairy, maker of Blue Bunny and other ice cream brands, and CEO Michael Paritee, a former General Motors executive that managed several advanced vehicle programs and has guided technology firms for more than a decade.

Optimized copper windings and rotors in electric motors are among the factors enabling the automotive industry’s transition to hybrid and pure electric power vehicles. However, current methods of manufacturing the windings are costly, inefficient, and limit designs in a way that also limits their performance.

ExOne and Maxxwell have successfully proved out a new concept for binder jet 3D printing a high-efficiency design in copper that eliminates many of the challenges that come with traditional manufacturing. Additional development and testing are now underway.

“When we 3D print it, a lot of the challenges just go away, and we can actually improve the performance of the motor itself,” Paritee said. “At Maxxwell, we’re taking the most sustainable, and additive manufacturing, point of view as possible to truly improve efficiency, reduce waste and optimize performance.”

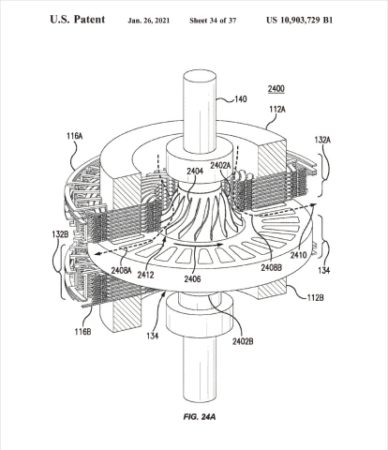

Ultimately, Maxxwell’s goal is to binder jet 3D print winding assemblies as a monolithic piece, eliminating the need for coil wrapping, bending, tooling, and welding of individual parts together.

When produced with binder jet 3D printing, the final part would require less manufacturing steps and energy utilization, as well as less material waste to produce – also resulting in components that are more efficient and deliver improved performance. What’s more, high-speed binder jetting is relatively affordable.

“The ExOne team is proud to work with both traditional manufacturers and visionary startups working to change the world with innovative concepts such as these,” said John Hartner, ExOne’s CEO. “As the automotive industry enters a new era of electrification, our world-class team of engineers stands ready to help solve some of the most pressing challenges with our binder jet 3D printing technology.”

![[해설] ST, NXP MEMS 사업 인수 완료… “자동차·산업용 센서 시장 싹쓸이 나선다” [해설] ST, NXP MEMS 사업 인수 완료… “자동차·산업용 센서 시장 싹쓸이 나선다”](https://icnweb.kr/wp-content/uploads/2026/02/MEMS_NXP.png)

![[심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다 [심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다](https://icnweb.kr/wp-content/uploads/2026/01/memory-market-3player-1024web.png)

![[심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다 [심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다](https://icnweb.kr/wp-content/uploads/2026/01/Perplexity-image-Edge-AI-industry1b-700web.png)

![[피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시” [피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시”](https://icnweb.kr/wp-content/uploads/2026/02/R41_0775-HM26-von-press-900web.png)

![[이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝 [이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝](https://icnweb.kr/wp-content/uploads/2025/07/OT-security-at-automotive-by-Gemini-Veo-1024x582.png)

![[기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지 [기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지](https://icnweb.kr/wp-content/uploads/2026/01/generated-edge-AI-4-in-1-01-1024web.png)

![[그래프] 국회의원 선거 결과 정당별 의석수 (19대-22대) 대한민국 국회의원 선거 결과(정당별 의석 수)](https://icnweb.kr/wp-content/uploads/2025/04/main-image-vote-flo-web-2-324x160.jpg)