Digitalisation in electrical automation

FFesto is deploying its products and services to meet the challenge of smart production for the future in the course of digitalization.

Festo, the world’s leading supplier of automation technology and technical education, is deploying its products and services to meet the challenge of smart production for the future in the course of digitalization. The company also relies on artificial intelligence and machine learning.

Festo is leading its customers and employees into the digital future. To this end, the company is developing new future-oriented concepts founded on the triad of innovative and energy-efficient technologies, intuitive human-machine collaboration, and education and further training. Festo will be demonstrating this triad at this year’s SPS IPC Drives in Hall 9, Stand 361.

![[#sps_live] Festo presents smart automation at SPS IPC Drives [#sps_live] Festo presents smart automation at SPS IPC Drives](https://icnweb.kr/wp-content/uploads/2018/11/CPX-IoT-Gateway-600.jpg)

Digitalization and Industry 4.0 – smart products for the future

It is only through self-organising components that production plants become really flexible and thus meet the constantly changing requirements. Consistent standards, norms and interfaces, such as the common OPC UA interface, create the conditions for smart products in the sense of “plug-and-produce” and industry 4.0. Festo has also integrated this universal communication interface into numerous components of electrical drive technology, such as the modular control platform CPX-E, the flexible transport system MCS® (multi-carrier system) and robot controllers.

In addition to integration into higher-level systems, data collection and evaluation play an important role. Here, Festo relies on artificial intelligence, among other things. Festo further expanded this expertise with the acquisition of Resolto Informatik GmbH in April. Resolto has developed a software solution that analyses and interprets data in real time and recognises and reports anomalies. In addition, the system continuously learns through permanent data analysis and expands its knowledge base. This machine learning enables intelligent process monitoring. At the trade fair, visitors can experience the software solution live at the Festo stand. In combination with the new modular controller CPX-E-CEC and the new servo drive CMMT-AS, real-time monitoring is possible. The application shows the detection of faulty batteries. A handling portal lifts the batteries. The Resolto monitoring software monitors the motor currents and position values of the axis. If anomalies occur, e.g. if the handling system grips an incorrect battery format, a message is generated.

Data collection and monitoring can be carried out either by the intelligent software solution close to the components, as with battery handling, or via the IoT gateway CPX-IoT in the Festo cloud. It connects components and modules from the field level, such as handling systems or electric drives, to the Festo Cloud via its OPC UA interface.

Festo is demonstrating the end-to-end connectivity of workpieces and mechanics up to the cloud with a modular production system for customisable USB sticks. This shows the combination of all Festo engineering tools – around the new Festo Automation Suite as well as components and solutions in hardware and software. Visitors can take their personal USB stick, with their name and picture, home as a souvenir of the fair.

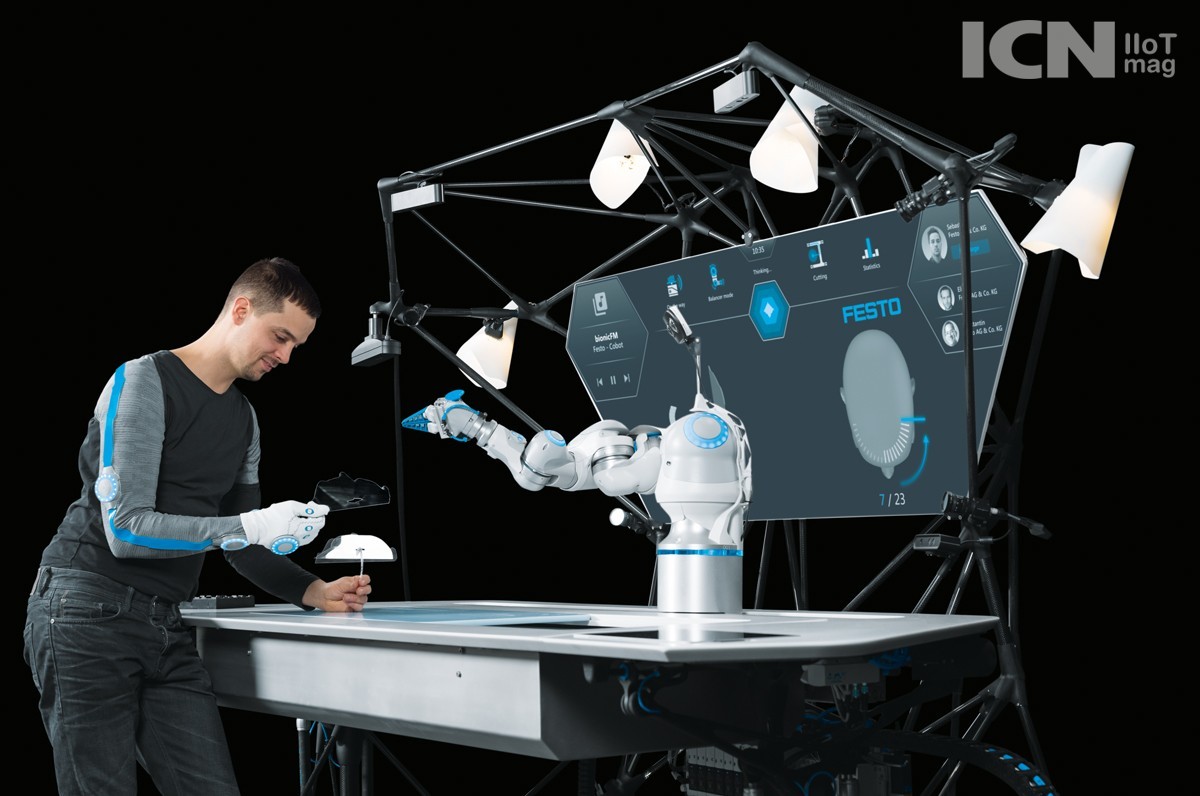

Human-Machine Collaboration of the Future

Learning systems with artificial intelligence and robots that work hand in hand with humans play a central role in the production of Lot size 1, the trend towards individualization of products. With the BionicWorkplace, Festo offers a unique concept for human-machine collaboration in the production of the future. In this concept, the bionic robot arm BionicCobot works together with numerous assistance systems and peripheral devices that are networked and communicate with each other. At the same time, artificial intelligence and machine learning methods make the BionicWorkplace a learning and anticipatory system that continuously optimises itself. How sensitive and flexible the human-robot collaboration with the BionicCobot works can be seen by the trade fair visitors in

Hall 9, Stand 361.

Qualification for industry 4.0

Festo Didactic will also be present at the stand with its latest educational offer in the field of automation technology. Increasingly intelligent systems and flexible production processes demand a new qualification of employees for operating digital and intelligent systems. For example, Festo Didactic has developed the cyber-physical learning platform “CP Factory” for practical knowledge transfer. The platform depicts the stations and processes of a real production plant in the form of a learning factory. In addition to this, Festo Didactic also offers many training courses for employees.

Established in 1925, the independent family-owned company based in Esslingen a.N., Germany, has been a driving force in automation for over 60 years and with its unique range of offers has become the world market leader in technical education. In addition to pneumatic drive technology, Festo has also been very successful in electrical automation for over 20 years.

![[해설] ST, NXP MEMS 사업 인수 완료… “자동차·산업용 센서 시장 싹쓸이 나선다” [해설] ST, NXP MEMS 사업 인수 완료… “자동차·산업용 센서 시장 싹쓸이 나선다”](https://icnweb.kr/wp-content/uploads/2026/02/MEMS_NXP.png)

![[심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다 [심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다](https://icnweb.kr/wp-content/uploads/2026/01/memory-market-3player-1024web.png)

![[심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다 [심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다](https://icnweb.kr/wp-content/uploads/2026/01/Perplexity-image-Edge-AI-industry1b-700web.png)

![[피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시” [피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시”](https://icnweb.kr/wp-content/uploads/2026/02/R41_0775-HM26-von-press-900web.png)

![[이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝 [이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝](https://icnweb.kr/wp-content/uploads/2025/07/OT-security-at-automotive-by-Gemini-Veo-1024x582.png)

![[기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지 [기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지](https://icnweb.kr/wp-content/uploads/2026/01/generated-edge-AI-4-in-1-01-1024web.png)

![[그래프] 국회의원 선거 결과 정당별 의석수 (19대-22대) 대한민국 국회의원 선거 결과(정당별 의석 수)](https://icnweb.kr/wp-content/uploads/2025/04/main-image-vote-flo-web-2-324x160.jpg)