Hymer uses Solid Edge and Teamcenter solutions to reduce physical prototypes of caravans and motorhomes by 80 percent

Using PMI has turned deriving individual variants into configuration. It has reduced the time required by 65 percent.

– Stefan Ziegler, Head of Industrialization R&D, Hymer

Freedom and comfort combined

Camping has been a popular outdoor recreational activity and a mode of accommodation for decades. In many countries, it is a substantial contributor to the tourism industry. The activity offers some of the most affordable lodging options. According to the Statista platform, about seven percent of all tourists visiting Germany in 2020 preferred camping over hotel accommodation. As the use of tents has significantly decreased over the past decades, recreational vehicles (RV) such as caravan trailers and motorhomes have become more popular. They provide campers with home-level comfort such as living areas, kitchen facilities and bathrooms.

Located in the spa town of Bad Waldsee in Southern Germany, Hymer GmbH & Co KG (Hymer) is among the pioneers of RVs. The company produced its first caravan trailer in 1957, followed by the first German motorhome in 1961. Hymer has become a household name emblematic for an entire vehicle category in Europe. The company is part of the Erwin Hymer Group and also designs and manufactures trailers under the Eriba brand. The Erwin Hymer Group belongs to the Thor Industries family of companies, uniting the vast majority of European and North American RV manufacturers.

Hymer has become an innovation and technology leader in the motorhome segment, combining innovation with Swabian virtues such as attention to detail and quality and made in Germany workmanship standards. “The five centimeters (two-inch) side walls combining aluminum skins on closed-cell PU provide insulation comparable to 80 centimeters (2 feet and 7 inches) of brick wall,” states Frank Heinrichsen, marketing manager at Hymer.

Fully digitalized product creation

Hymer engineers designed the VisionVenture, a concept camper van, by weaving a digital thread along the entire product design process. As in all their designs, they created a comprehensive digital twin of the vehicle using software from the Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software, hardware and services.

For computer-aided design (CAD), Hymer engineers in all European locations use Solid Edge® software. For VisionVenture, they imported models that an external industrial designer had created using NX™ software. “Solid Edge has a supportive user interface, so it is easy to learn; new colleagues only require minimal training,” says Stefan Ziegler, head of industrialization research and development (R&D) at Hymer. “At the same time, this 3D CAD software has everything we need to create a comprehensive digital twin of the vehicles, including powerful tubing capabilities.” In Hymer camper vans, fluid tubing and electrical harnesses play a key role. For designing and routing those, they rely on the Solid Edge Xpress Route 3D routing application.

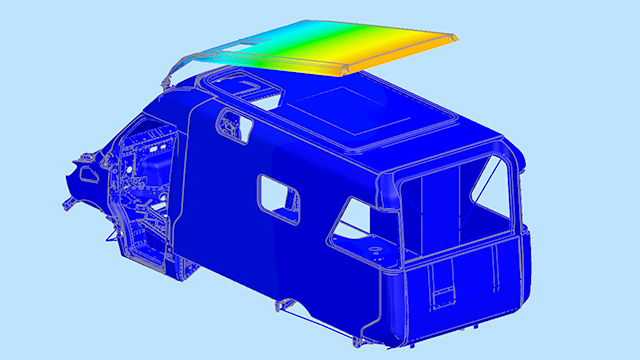

The design engineers verify the structural integrity of our designs using finite element modeling (FEM) analyses. For everyday basic verifications, they use the capabilities of Solid Edge. More in-depth stress analyses are outsourced to The Team Technology (TTT), an automotive lightweight construction department in the Erwin Hymer group. They use Simcenter™ 3D software for FEM analyses. This two-stage verification process establishes a knowledge gain during the early phases of product design, reducing the number of physical prototypes required.

Virtual prototyping

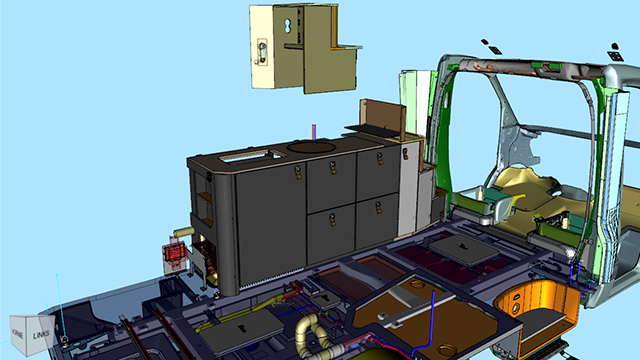

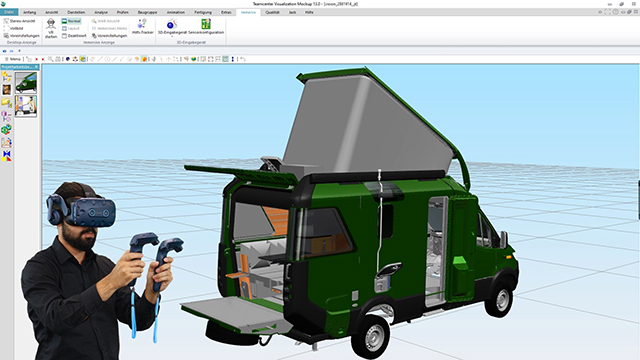

Hymer uses Teamcenter® software to build prototypes of their vehicles in virtual reality (VR). Teamcenter visualization concept capabilities are provided as an add-on to the Teamcenter lifecycle visualization suite. The caravan experts import the digital twin created using Solid Edge and build digital mockups of the entire vehicle or a part of it to detect and resolve issues.

Ergonomic design verification is vital and using VR gear is an easy way to reveal if the solutions designed are practical. “By using the digital mockup capabilities of Teamcenter visualization, we can identify and resolve issues before they become costly problems,” says Heinrichsen. “Virtual prototyping helped us reduce physical mockups and prototypes by 80 percent.”

Teamcenter VR uses the JT™ file format in viewing and analyzing 3D designs. Importing design data from Solid Edge does not require any data preparation or conversion because the geometry information is received in the JT data format.

Hymer engineers generally use the JT data format for all exchange of geometry data between different software products. For many purposes, most of the information carried in native CAD data is not required. In most cases, geometry information is all that is needed and historical data would merely be a ballast. “We do not need three days for data translation and cleansing anymore,” explains Ziegler. “Using the JT data format, we can import and consolidate geometry data in minutes versus days, even if they originate from different software systems.” This is frequently needed when bringing together Hymer’s mechanical and wire harness designs created using different software products in one model using Teamcenter Visualization.

Additionally, using JT for model data exchange does not require users to be equipped with CAD software to view 3D designs using the free JT2Go viewer. This eases collaboration with suppliers and external partners based on rich design data.

One digital twin, many uses

Hymer engineers use Rapid Author for Teamcenter (formerly known as Cortona 3D) to create all documentation. They benefit from its work instruction component to create electronic instructions for assembly lines.

“Workers were enthusiastic about the dynamic assembly instructions using 3D models,” says Ziegler. “They particularly liked the ability to turn models to better see things often hidden in drawings.”

This also helped accelerate onboarding and training new employees in production. In engineering, Siemens’ solution partner ISAP AG supports Hymer with software training. For marketing and sales, Hymer engineers create life-like and often animated renderings. These are also based on 3D model data from Solid Edge in the JT data format.

These effects are even stronger if there is only one digital twin, even if a product comes in numerous variations, as Hymer caravans and motorhomes usually do. “Everything we create starts out as a 150 percent model that must be reduced to a 100 percent model to fit individual requirements,” says Heinrichsen. Hymer engineers have recently started enriching their models with product and manufacturing information (PMI). “Using PMI has turned deriving individual variants into configuration,” Ziegler confirms. “It has reduced the time required by 65 percent.”

Using the digital twin created in Solid Edge as the single source of truth for all these purposes enables all data to be bot ubiquitous and associative. This allowed Hymer to eliminate distributed information silos and some notorious sources of error associated with this data separation. Additionally, after modifications, everyone involved can immediately resume work on the basis of valid, up-to-date information.

https://www.hymer.com/de/en/technology-innovation/vision-venture

![[해설] ST, NXP MEMS 사업 인수 완료… “자동차·산업용 센서 시장 싹쓸이 나선다” [해설] ST, NXP MEMS 사업 인수 완료… “자동차·산업용 센서 시장 싹쓸이 나선다”](https://icnweb.kr/wp-content/uploads/2026/02/MEMS_NXP.png)

![[심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다 [심층분석] AI 데이터센터가 삼킨 메모리 시장, ‘슈퍼사이클’ 넘어 ‘구조적 격변’ 시작됐다](https://icnweb.kr/wp-content/uploads/2026/01/memory-market-3player-1024web.png)

![[심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다 [심층기획] 클라우드를 넘어 ‘현장’으로… 인텔, 산업용 엣지 AI의 판을 흔들다](https://icnweb.kr/wp-content/uploads/2026/01/Perplexity-image-Edge-AI-industry1b-700web.png)

![[피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시” [피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시”](https://icnweb.kr/wp-content/uploads/2026/02/R41_0775-HM26-von-press-900web.png)

![[이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝 [이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝](https://icnweb.kr/wp-content/uploads/2025/07/OT-security-at-automotive-by-Gemini-Veo-1024x582.png)

![[기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지 [기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지](https://icnweb.kr/wp-content/uploads/2026/01/generated-edge-AI-4-in-1-01-1024web.png)

![[그래프] 국회의원 선거 결과 정당별 의석수 (19대-22대) 대한민국 국회의원 선거 결과(정당별 의석 수)](https://icnweb.kr/wp-content/uploads/2025/04/main-image-vote-flo-web-2-324x160.jpg)