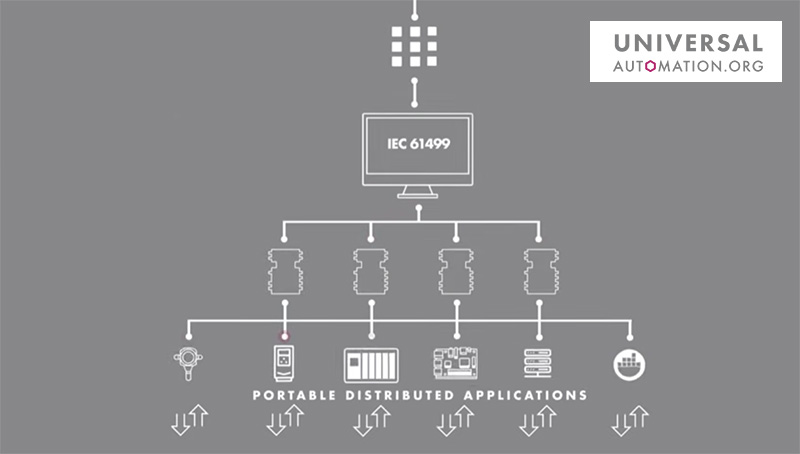

Industrial leaders and pioneers have joined together to form UniversalAutomation.org (UAO) and advance the world of industrial automation. For the first time, vendors, end users, OEMs and academics will share a common automation software layer across their automation technology regardless of brand. This technological collaboration will drive the development of an ecosystem of portable, interoperable, “plug and produce” solutions, creating an entirely new category of industrial automation.

Portability is already a reality in other market sectors. For example, mobile applications are developed to run across different smartphone vendors, enabling rapid advances through collective innovation. Until now, the industrial world has worked differently, with closed proprietary architectures and hardware-dependent software. UniversalAutomation.org will create a new era of openness and collaboration, decoupling software and hardware by sharing a reference runtime implementation of the IEC 61499 standard.

“We are excited to be part of UniversalAutomation.org because it promises to be a complete gamechanger,” said Jac Opmeer, Principal Automation Engineer at Shell Global Solutions B.V. “It opens up a new world of possibilities for organisations like ours. Unlocking valuable data currently buried in proprietary systems, making the connectivity and deployment of new technologies like AI quick and simple. As part of UniversalAutomation.org we are actively collaborating with and supporting like-minded organisations to create an exciting new open era in operations and automation.”

UniversalAutomation.org will provide the basis for interoperable and portable automation software that can run with almost any Universal Automation-compliant hardware, creating an entirely vendoragnostic ecosystem for automation software development. By merging both the information technology (IT) and operational technology (OT) worlds, the organization seeks to unleash the full potential of Industry 4.0.

“The creation of UniversalAutomation.org is the dawn of a new era within automation technology; over the course of the next five years, it will create a sea change for the future of automation software development,” said Dmitrii Drozdov, Chief Technology Officer at Flexbridge. “We are delighted to be a part of UniversalAutomation.org, driving the development of a “plug and produce” system which will help the industry keep up with the increasing demands of flexible manufacturing. There is no doubt that as members continue to join the organization and reap the benefits of collaboration and openness, that industry-wide change will follow.”

“UniversalAutomation.org brings together vendors and users of technology, opening up the opportunity for continuous dialogue between members to share their knowledge. We’re excited to work with other members to enhance and develop our research and help combat the challenges currently facing industry,” said Valeriy Vyatkin, Professor of Electrical Engineering, Aalto University.

“The IEC 61499 standard will help industry have a common platform for different types of software functionalities in automation, allowing organisations to achieve a certain level of reliability and predictability, as well as increasing flexibility of production plants.”

“Wood is excited to be part of defining the future of automation and transforming profitability and productivity for the customers in our industrial markets. UAO technology will enable business innovation, increased digital adoption and agility with its open, interoperable and portable solutionsbuilding business resiliency and empowering our clients to be future-ready,” says German Carmona, President of Wood’s Applied Intelligence business.

Current founding & intended members include: Aalto University, Advantech, Asus, Belden, Cargill, eaw Relaistechnik GmbH, ESA, ETP, Flexbridge, Georgia-Pacific, GR3N, Hirschmann, HTW Berlin, Intel, Jetter, Johannes Kepler University Linz, Kongsberg Maritime, Luleå Technological University, Lumberg Automation, Phoenix Contact, ProSoft, R. Stahl, Schneider Electric, Shell, VP Process, Wilo, Wood and Yokogawa. Others are expected to join soon, with the organization actively recruiting new members.

Members are working together to develop and adopt the next generation of Universal Automation solutions by collectively incrementing a runtime following shared source principles. Members will have access and the ability to shape the next generation of automation.

UniversalAutomation.Org is actively recruiting new members. All entities looking to help advance industrial automation are encouraged to join.

Time for Universal Automation

“Industrial operations are undergoing a total transformation,” said John Conway, President of UniversalAutomation.org. “As the IT sector has proven, advances in machine learning, augmented reality, real-time analytics, and the IoT hold great promise for step change advancements in performance, agility, and sustainability. However, within industry this promise is being held back by closed and proprietary automation platforms that restrict widespread adoption, hamper innovation, are challenging to integrate with third-party components, and are expensive to upgrade and maintain. Using a shared runtime changes all that.”

Greg Boucaud, Chief Marketing Officer of UniversalAutomation.Org commented: “With the formation of UniversalAutomation.org, we are hitting the reset button on automation technology. Using the IEC 61499 standard for distributed systems, we can create a new, open industrial environment that will lead to a more sustainable, efficient future. UniversalAutomation.org will remove the barriers to innovation in automation by decoupling

hardware and software and providing end users with the freedom they have been asking for — to easily integrate different technologies regardless of where they came from and fully optimize their automation systems.”

Industry advancement with interoperable automation software

Adopting a common runtime, shared across vendors, will provide limitless opportunities for growth and modernization across industry. The ARC Advisory Group found this move could save the industrial market $30 billion each year, which is currently spent servicing and maintaining the installed base of proprietary systems alone.

UniversalAutomation.org members anticipate the adoption of this reference implementation-based approach to industrial automation to deliver a range of benefits, including:

• Portability and reuse of software components on different systems, improving return-on investment for software intellectual property (IP)

• Greater Innovation through the faster integration of new technologies and systems, development of new business models, easier connectivity, and flexibility to deliver customer requirements at greater speed

• Extending the lifespan of existing industrial tools, devices and systems, and easier upgrading of systems reaching their end of life

• Simplified training and skills (with teams only needing to learn one common system), making automation industry OT entry more accessible to IT professionals and the new generation of automation professionals

• Development of AppStore-like platforms to share apps around automation applications

![[심층분석] 현대차그룹 ‘모베드 얼라이언스’ 출범… 로보틱스 생태계 확장의 신호탄 [심층분석] 현대차그룹 ‘모베드 얼라이언스’ 출범… 로보틱스 생태계 확장의 신호탄](https://icnweb.kr/wp-content/uploads/2026/03/mobed얼라이너스.jpg)

![[기고] 엔비디아 ‘루빈’의 독주를 멈춰라… AMD·인텔의 ‘실리콘 틈새’ 돌파 전략 [기고] 엔비디아 ‘루빈’의 독주를 멈춰라… AMD·인텔의 ‘실리콘 틈새’ 돌파 전략](https://icnweb.kr/wp-content/uploads/2026/03/NVIDIA-RUBIN-platform-and-whang-1024x545.jpg)

![[분석] 엔비디아 ‘루빈(Rubin)’ vs 웨이퍼 공급망: 2026년 AI 패권의 임계점 [분석] 엔비디아 ‘루빈(Rubin)’ vs 웨이퍼 공급망: 2026년 AI 패권의 임계점](https://icnweb.kr/wp-content/uploads/2026/03/NVIDIA-RUBIN-GPU.jpg)

![[피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시” [피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시”](https://icnweb.kr/wp-content/uploads/2026/02/R41_0775-HM26-von-press-900web.png)

![[이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝 [이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝](https://icnweb.kr/wp-content/uploads/2025/07/OT-security-at-automotive-by-Gemini-Veo-1024x582.png)

![[기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지 [기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지](https://icnweb.kr/wp-content/uploads/2026/01/generated-edge-AI-4-in-1-01-1024web.png)

![[그래프] 국회의원 선거 결과 정당별 의석수 (19대-22대) 대한민국 국회의원 선거 결과(정당별 의석 수)](https://icnweb.kr/wp-content/uploads/2025/04/main-image-vote-flo-web-2-324x160.jpg)