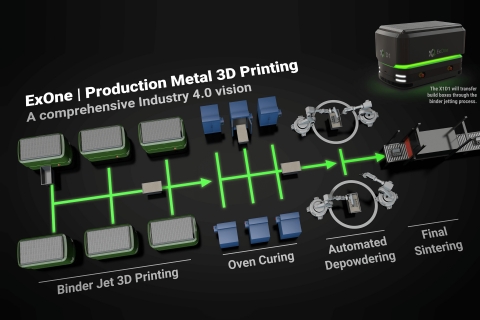

The ExOne Company debuted a concept rendering of the new X1D1 automated guided vehicle, which will enable efficient transport of 3D printed build boxes through the binder jetting process.

The X1 160Pro™ extra-large production metal 3D printer, which begins shipping to customers later this year, will be offered with either a standard conveyance system or the new X1D1 to provide manufacturers with greater layout flexibility and efficiency. The AGV can support multiple 3D printers and processes efficiently, reducing the total footprint of the system and simplifying timed movements between processes.

“As part of our discussion with manufacturers, we’ve updated our vision for the production binder jetting work cell, developing an option that provides high-volume manufacturers with more intelligent flexibility and better use of factory space,” said John Hartner, ExOne CEO.

The X1 160Pro will also be offered with ExOne Scout, a previously-announced Industry 4.0 app that provides real-time machine monitoring and analysis of production 3D printers on a wide range of digital devices, including smart phones and watches. Scout is enabled by Siemens MindSphere, an Internet-of-Things operating system with multilayered security.

“While ExOne’s production metal 3D printers will remain the centerpiece of our digital manufacturing vision, we’re looking to streamline the entire sequence of processes around our systems with automation, software and remote monitoring and controls,” Hartner said. “ExOne Scout and the X1D1 are moving us toward a complete digital manufacturing package that is smart and efficient.”

A Complete Binder Jetting Vision

The X1 160Pro is ExOne’s 10th metal 3D printer and the company’s largest system of its kind, capable of 3D printing a wide range of metal and ceramic materials into high-density precision parts with exclusive binder jetting technology. With print speeds topping 10,000 cc/hour, depending on print material, the X1 160Pro is designed to deliver the best quality part at production speeds.

Binder jetting is a groundbreaking 3D printing process that uses a digital file to quickly inkjet a binder into a bed of powder particles — metal, sand or ceramic — creating a solid part one layer at a time. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object.

The new X1D1 AGV will lock into place at the front of the 160Pro, and will be able to roll a build box into and out of the machine. With a build volume of 160 liters, a full build box of metal powder will often weigh more than 700 kilograms, or more than 1,500 pounds.

After printing, the X1D1 will transport the build box to a curing oven, where the parts are dried, before moving to an automated depowdering and cleaning station, enabled by robot arms and other yet-to-be-announced innovations, before final sintering.

![[심층분석] 현대차그룹 ‘모베드 얼라이언스’ 출범… 로보틱스 생태계 확장의 신호탄 [심층분석] 현대차그룹 ‘모베드 얼라이언스’ 출범… 로보틱스 생태계 확장의 신호탄](https://icnweb.kr/wp-content/uploads/2026/03/mobed얼라이너스.jpg)

![[기고] 엔비디아 ‘루빈’의 독주를 멈춰라… AMD·인텔의 ‘실리콘 틈새’ 돌파 전략 [기고] 엔비디아 ‘루빈’의 독주를 멈춰라… AMD·인텔의 ‘실리콘 틈새’ 돌파 전략](https://icnweb.kr/wp-content/uploads/2026/03/NVIDIA-RUBIN-platform-and-whang-1024x545.jpg)

![[분석] 엔비디아 ‘루빈(Rubin)’ vs 웨이퍼 공급망: 2026년 AI 패권의 임계점 [분석] 엔비디아 ‘루빈(Rubin)’ vs 웨이퍼 공급망: 2026년 AI 패권의 임계점](https://icnweb.kr/wp-content/uploads/2026/03/NVIDIA-RUBIN-GPU.jpg)

![[피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시” [피플] “생성형 AI 넘어 ‘피지컬 AI’의 시대로… 2026 하노버메세, 제조 혁신의 해법 제시”](https://icnweb.kr/wp-content/uploads/2026/02/R41_0775-HM26-von-press-900web.png)

![[이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝 [이슈] 스마트 제조의 방패 ‘IEC 62443’, 글로벌 산업 보안의 표준으로 우뚝](https://icnweb.kr/wp-content/uploads/2025/07/OT-security-at-automotive-by-Gemini-Veo-1024x582.png)

![[기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지 [기자칼럼] 제어반의 다이어트, ‘워크로드 컨버전스’가 답이다… 엔지니어를 위한 실전 팁 7가지](https://icnweb.kr/wp-content/uploads/2026/01/generated-edge-AI-4-in-1-01-1024web.png)

![[그래프] 국회의원 선거 결과 정당별 의석수 (19대-22대) 대한민국 국회의원 선거 결과(정당별 의석 수)](https://icnweb.kr/wp-content/uploads/2025/04/main-image-vote-flo-web-2-324x160.jpg)